Alumina Ceramic in Ash Handling

Alumina Ceramic in Ash Handling

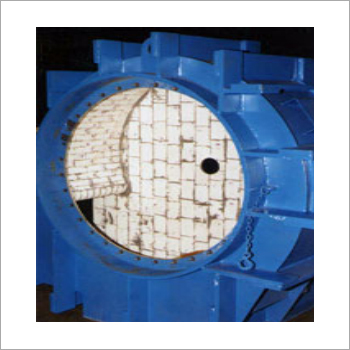

Bends and Y-Pieces

One of the major factor influencing bend wear rate is the conveying velocity of the ash, density and the ash particle size. Lean-phase system normally maintain velocity between 20-27 m/s. The metal bends and pipes required to be replaced very frequently. To check the wear bends are lined with Alumina Ceramic liners. In lower ID bends, wear resistant Ni-Hard castings are also used. In this section we will demonstrate our Alumina Ceramic lined bends.

One of the major factor influencing bend wear rate is the conveying velocity of the ash, density and the ash particle size. Lean-phase system normally maintain velocity between 20-27 m/s. The metal bends and pipes required to be replaced very frequently. To check the wear bends are lined with Alumina Ceramic liners. In lower ID bends, wear resistant Ni-Hard castings are also used. In this section we will demonstrate our Alumina Ceramic lined bends.