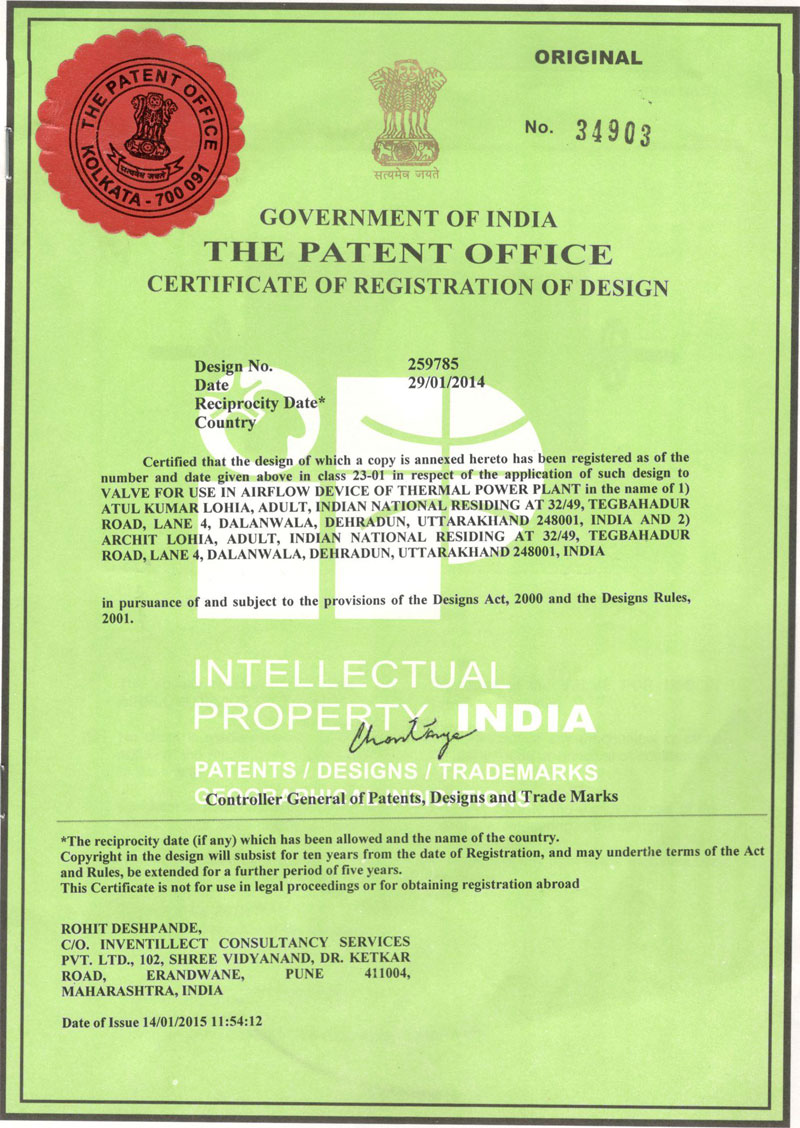

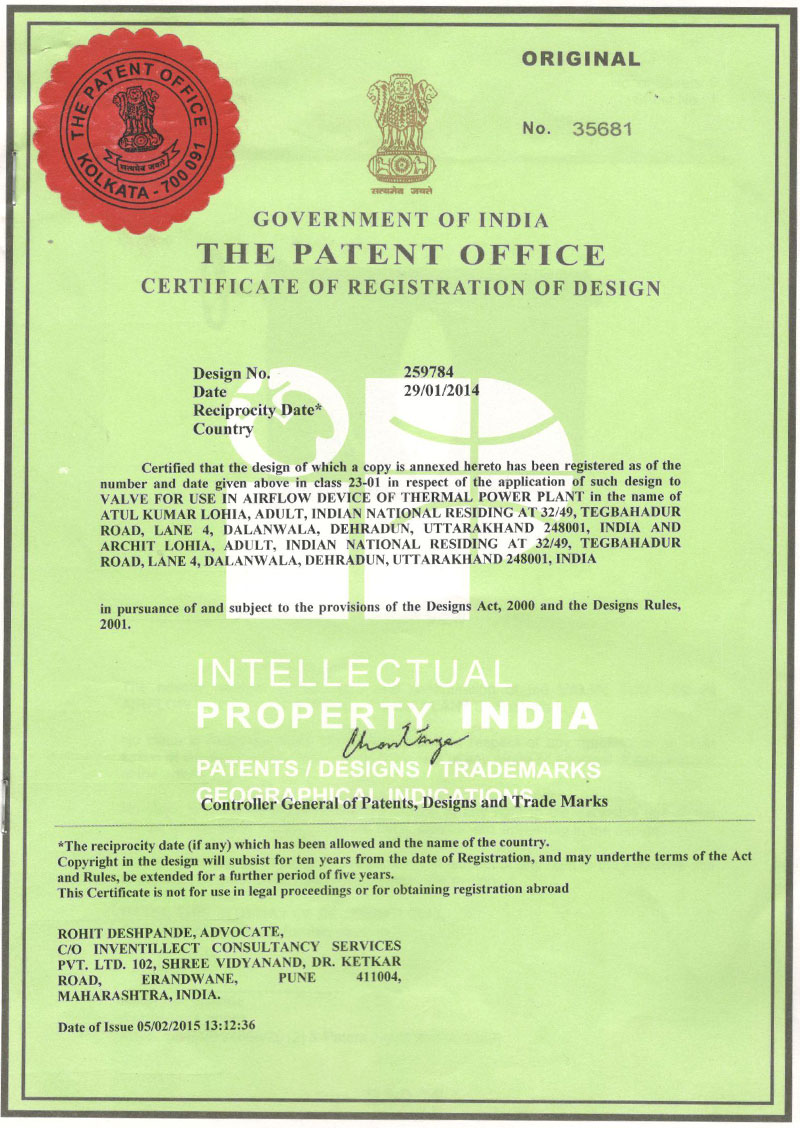

Alumina Ceramic

We provide Wear Resistance Solution through Alumina Ceramic Coal Pulverizer and Pipe Line. Herein, pressurized air is given to cause erosion that blew away entrained abrasive solid coal particles lying on the surface. If the angle of impingement is less than 30 degree there are chances of corrosion and if angle of impingement is more than 30 degree to the surface, strong air pressure resulting in erosion dislodge the particles from the mill internals. Further, Alumina Ceramic is used to repair the surfaces of coal mills and render absolute performance on the wear resisting surfaces.

A study to understand the erosion pattern of coal mill internal depicts that coal and air mixture takes number of turns and then reaches to multiple port outlets and due to changes in the direction of the flow, the particles accumulate to the “red marked” area of coal pulverizer.

Coal Flow Concentration Distribution within the model Pulverizer

The accumulated particles have tendency to cause wear during machining, lapping, and polishing. Here, two body abrasive wear occurs in coal dust and mill internals as one surface cuts material from the body and internal, which often transforms into three body abrasion as the debris act like abrasive which is mixed with coal dust on the internal surface of the mill. Alumina liners can be used to minimize abrasion in this coal accumulation area of the pulverizer.

BMW Alumina Ceramic Liner is suitable for Mill Discharge Valves, Coal flow Orifices, Coal Pipe and Bends, Lined Pipe, Pulverizer Coal, and others.