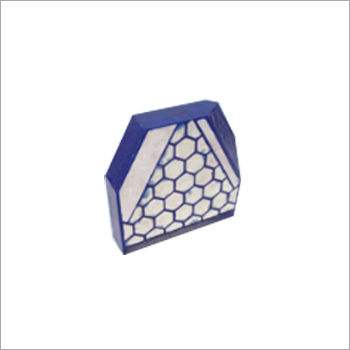

Lining in ChuteAlumina Ceramic Lined Coal Chute are proven to increase production by promoting material flow of congested materials due to its low surface friction. These engineered Lined Coal Bunkers are the perfect solution when there is a need to reduce or eliminate arching and erratic material flow challenges. All these makes our products flawless and demanding in the market place.

Features

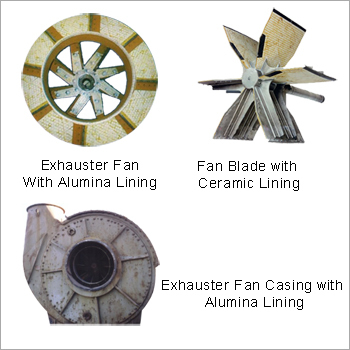

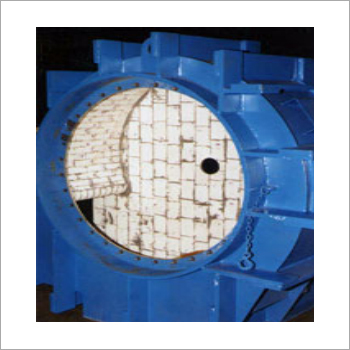

Alumina Ceramic in Mill Fan or ID Fan and their CashingWe are prime manufacturer of Mill Fan Impeller which are lined with Alumina Ceramic Liners to reduce the wear and erosion in Impellers and casings. These highly reliable ID Fan Impeller is equipped with all technological constraints to deliver high-end performance. Our engineered Alumina Ceramic Casing Fans are made according to the technical specifications of international standards, considering all the important quality parameters. This is is the main reason, our products are highly appreciated in the industry.

Features

- Stable Performance

- Low Energy Consumption

- Less Maintenance Cost

- Long Application Life

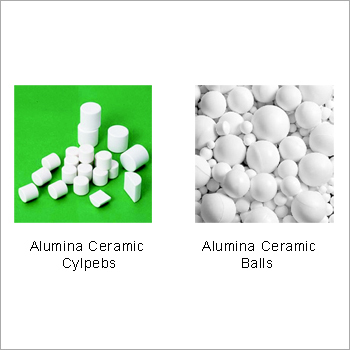

BMW Alumina Ball and Cylpebs has advantage of high density, regular shape and superior milling efficiency, BMW Alumina Ball and Cylpebs have proved to be excellent for grinding processing of ceramic bodies and glaze materials in tile industries and pharma base grinding in pharmacy.

There are lots of merits for it, for instance, the stronger resistance to wear, nil absorbing, more stable chemical properties, and so on. It is capable of enduring the corrosion of acid, alkali, and organic solvent. In addition, due to lower wear rate it produces lowest contamination in the grinding material.

Alumina Ceramic Lined Steel Plant Sinter Pot

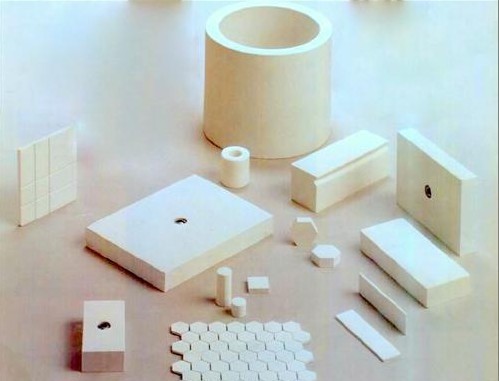

Our effective Alumina Ceramic Tiles are made of high-grade raw material such as alpha aluminum oxide, fine grains, etc., which make them perfect for future usage. These reliable Alumina Ceramic Steel Plants have thin wear resistant linings which can be formed in various pre-engineered modules to give them custom shapes and sizes. Owing to striking attributes of high wear resistance, smooth surface and high tensile strength, our products are appreciated in the market.

Features

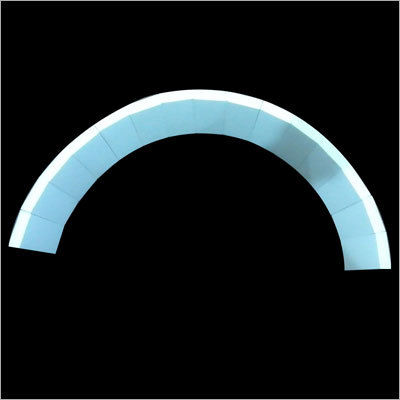

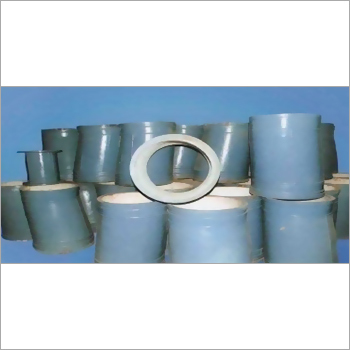

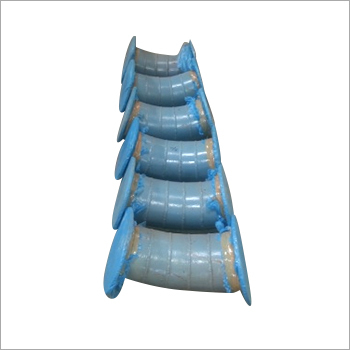

Bends and Y-Pieces

One of the major factor influencing bend wear rate is the conveying velocity of the ash, density and the ash particle size. Lean-phase system normally maintain velocity between 20-27 m/s. The metal bends and pipes required to be replaced very frequently. To check the wear bends are lined with Alumina Ceramic liners. In lower ID bends, wear resistant Ni-Hard castings are also used. In this section we will demonstrate our Alumina Ceramic lined bends.

We specialise in manufacturing Ash Bends, which are specially coated with Ni-Hard. Ni-Hard is a metal with chrome content of 1.4% to 28%. It is an abrasive iron for low and high stress abrasion in Mining, Milling, and Earth Handling uses. Ni-hard is best in preventing abrasion in bends. Our range of Ni-Hard Ash Bends has shown excellent performances and has good wear & tear.

We, BMW Steels Ltd., have strong market presence as an innovative & advanced manufacturer of Alumina Ceramic Lined Coal Pipe Bends. These Bends find wide usage in various industries such as steel, mining, milling, chemical, thermal power plant, cements, melting, and more. The offered Lined Coal Pipe Bends are demanded in the market owing to their outstanding tolerance to erosion. Ceramic liners fitted in the interlock mechanism inside these pipe bends protect them from erosion and prevents any incidence of leakage.

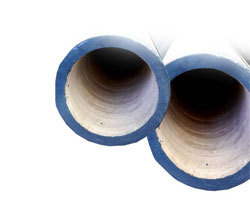

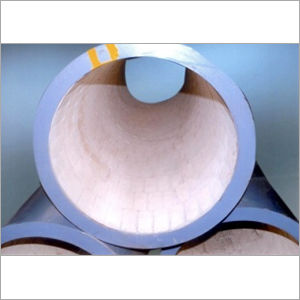

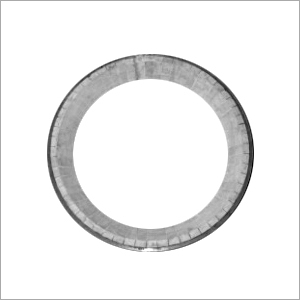

Alumina Ceramic Lined Straight Pipes prevents the pipes from wear and erosion. These linings are performed on straight pipes in such a way that it protects the pipe from erosion and abrasion. These linings are having high hardness and good wear resistance and excellent electrical insulation properties.

Alumina Liners for straight pipes are available from 32mm ID to 1000mmID. It is recommended to use liners in ring form for sizes up to 150 mm ID. Sizes beyond 150mm ID, liners in tile form are recommended.

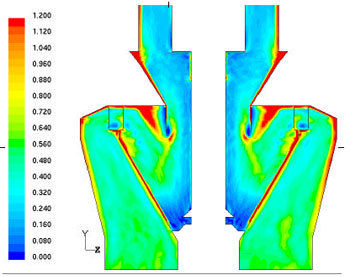

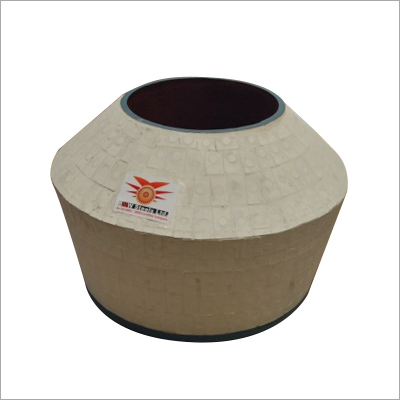

We are capable of manufacturing Inner Cone for various designs of 210MW, 300MW, 500MW and 660MW and 800MW mills based on buyers drawings. We can also supply exact designs as per samples and provide fittment guarantee for the same. Our inner cone have been successfully installed in various NTPCâs, state electricity boards and various other power plants

Transition Piece is widely known for strong wear protection. We are capable of manufacturing MDV for various designs of 210MW, 300MW, 500MW and 660MW and 800MW mills based on buyers drawings. We can also supply exact designs as per samples and provide fittment guarantee for the same. Our MDV have been successfully installed in various NTPC's, state electricity boards and various other power plants.

The most reliable Ventury Vane offered by us is manufactured with superior quality raw material that is procured from reputed vendors of the industry. This product is known for robust construction, compact design, and durability. Along with this, we offer Venturi Tubes, which are manufactured with aluminum, stainless Steel metal, and rubber. These tubes are available in various types and sizes as per customer requirements. These reliable Venturi Tubes play the roles of inductor of second airflow. After removing the filter bags, dusts as well as airflow with high speed pass through these Venturi Tubes. It can induce another second airflow blowing closed air into the filter bag. Also these tubes develop the pulse blowing strength with high efficacy.

Our easy to install Ventury Tubes are known for stable performance as well as low pressure loss. Exemplifying green technology, these tubes save the required energy during their operation. Used for measuring the volume of flaw, these high quality Venturi Tubes are strictly checked at our end before the final shipment.

The Best quality Ventury Outlet is manufactured with cutting-edge technology and premium quality raw material, which is obtained from renowned vendors of the industry. These products are specially manufactured to serve various industries like Cement, Power Sector, Ceramic, Mineral Processing, Construction, and Mining. Being a quality conscious company, we examine the reliable Ventury Outlets on the basis of various quality parameters like construction, durability, design, and weight.

Our best quality Ventury Outlet is carefully stored at our spacious warehousing unit before packaging. This is done carefully for the safe shipment of the product. In addition to this, our Outlet Ventury is designed and manufactured as per customers' requirements as well as specifications. This helps us to serve the customers with their desired design of Ventury Outlet. With strong resistance to wear, our outlets represent excellent engineering techniques and methodology. After final manufacturing, we store these Ventury Outlets with caution and deliver to the customer's end with high quality export packaging.

Bowl Mill body is prone to wear due to abrasion of pulverized coal. To protect it from wear we fix it with Alumina Ceramic liners, thus making it durable. The liner not only reduces wear but also increase its strength and performance. Alumina ceramic results in considerable increase of the material fracture toughness. It is the most important, widely used and cost effective oxide ceramic material with structural formula AL2O3. Bowl Mill Body fitted with Alumina Ceramic have been successfully installed in various NTPC's, state electricity boards and various other power plants.

BMW Steels is offering high quality Grinding Media Balls and Grinding Media Cylpebs as a renowned manufacturer. The high quality Alumina Ceramic Lined Grinding Media Balls and Cylpebs are famous for high density, regular shape and also high milling functionality. These products are excellent for all grinding procedure of ceramic bodies. Also used in pharma base grinding, these products prevents destructive wear in conveying as well as processing. We strictly examine these products on the basis of various quality parameters then send to the warehousing unit for safe storage.

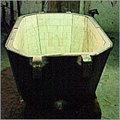

BMW Steels Ltd. has specialization in manufacturing, exporting and supplying ceramic lined

coal bunkers and chutes. These products are some of our most popular parts of

Coal Ash Handling Equipments. The lining done on the

coal bunkers allows increased flow of the coal, which it is passed through the bunkers and chutes. It allows unbelievable resistance against wear and tear apart from having highest impact strength. These parts of

ash handling equipment also have surpassing resistance against abrasion and corrosion.

Its specific features are:

-

Low coefficient of friction

-

No moisture abortion

-

Resistance against abrasion, chemical and corrosion

-

Weldable liners are available

We are manufacturing Bends and Y-Piece that are critical part of

Coal Ash Handling Equipments. Considering the importance of precision dimensioned Bends and Y-Piece, it becomes pivotal to determine their wear rate. For this, three factors play a major role - 1) conveying velocity of ash, 2) density of the ash and 3) size of ash particles. To reduce the wear rate of these

ash handling equipment parts, alumina ceramic is used in the systems. For the benefit of clients, we also offer wear resistant Ni-Hard castings that have the purpose of analyzing the wear possibility. In this regard, the expertise of BMW Steels Ltd. resides in filling the linings in casings developed at our works.

Application areas

-

Aluminum plants

-

Cement plants

-

Coal and mineral washeries

-

Coal fired thermal power projects

-

Mineral processing units

-

Steel plants

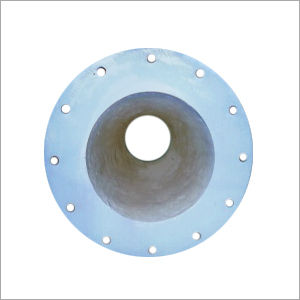

BMW Steels Ltd. has specialization in manufacturing, exporting and supplying Ash Pump Volute Casings that are categorized into parts of Coal Ash Handling Equipments. We offer lined Ash Pump Volute Casings to client which is helpful in reducing the severe erosion of the product, thereby reducing the overall maintenance cost.

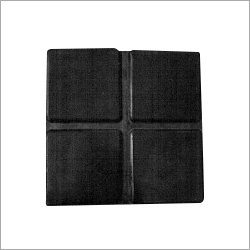

Reliably meeting clients requirements, BMW Steels Ltd., is a reliable manufacturer, supplier and exporter of

Metal Backed Impact Pads. These are highly demanded in metallurgy, construction, material handling and other applications to protect materials from getting damaged. Innovative design of these pads minimizes the shock due to fall or scattering. Also, these

Metal Impact Pads are coated with an anti skid treatment solution to ensure the safety of the operator. Lightweight and low density of these pads make them easy to shift, place and use. The offered

Impact Pads also protect the working floor from the shock of machines and materials.

With high-strength metal attached to their base, these pads are stable, rigid and perform with utmost efficiency to minimize corrosion and lower down the cost of production. Good cleaning property of our

Metal Backed Impact Pads make them suitable for applications where the job is tough and involves to much of dust. Moreover, our

Metal Impact Pads are appreciated in the market owing to their high load bearing capacity and abrasion resistance.

Features:

-

Excellent Compressive Property

-

Abrasion Resistant Coating

-

Pressure Minimizing Design

-

Goad Corrosion Control

We, BMW Steels Ltd., have earned high market goodwill as a manufacturer of Anti Skid Tiles. These are extensively used in different application areas such as business centre, hospitality, education, healthcare, supermarket, and more. With unique impact & feel, our Skid Tiles are highly durable and have complete resistance to scratch and abrasion. These tiles easily stick to the base surface and don't go off without the applying extreme pressure.

Gripping surface of our Anti Slip Tiles zeroes the incidents of slipping, falling and sliding and ensures the safety of people walking across. Strong tolerance to corrosion caused by chemicals has made our tiles highly suitable for use in areas inclined to chemical usage. The Eco-friendliness of our offered Anti Skid Tiles promotes their use in all types of construction purposes. Also, these tiles have a good anti-static feature which makes them more safe and reliable.

We offer our industrial customers solutions in form of chemically bonded ceramic that are designed and developed to provide desired protection to Pipe internals. As a process slurry generated through bottom ash system and fly ash system is discharged through pipelines to slurry pump through ash sump. As there is high density and velocity of ash slurry in sump, erosion possibilities on surface is high. Hence, the use of CBC is increasing in power plants as their preferred lining support.

Advantages:

CBC helps in safeguarding system internals that move large volumes of slurry through process

These are also highly used in systems installed for disposal of ash from fossil fuel power plants

CBC helps in decreasing the possibility of friction and in turn erosion through pipelines that is caused by drag against pipe walls.